What is concrete mix ratio calculator?

Concrete mix ratio calculator is the calculation of concrete mix ratio by the concrete grade, cement grade, and cement percentage. What and how soved calculator calculates concrete mix ratio? We will look in next paragraphs.

Calculator abbreviations:

M= mix

C= cement

S= sand

A= total aggregate

A10= 10mm aggregate

A20= 20mm aggregate

A40= 40mm aggregate

Coefficient to gain concrete strength with or without admixture:

Coefficient to gain concrete strength is the relation of concrete compressive strength (Concrete grade) and cement compressive strength (Cement grade) with the percentage of cement used in concrete mix.

Formula,

Coefficient to gain concrete strength= concrete compressive strength/(Cement compressive strength*cement percentage in mix*0.01)

Coefficient to gain concrete strength is totally based on 28days cube test in lab with various percentage of cement or mix proportion. And also plot a graph between Coefficient and cement percentage in mix, and found maximum coefficient in a particular cement percentage than create a economical mix design of cement concrete.

When we will used admixture to gain concrete strength then also our Coefficient increased 30 to 60 percent due to our concrete compressive strength increased.

Nominal mix ratio with cement percentage and Coefficient to gain concrete strength-

Example- Suppose 18% cement with OPC-33 grade used at concrete trial mix and found 28days compressive strength of cube test 21N/Sqmm. Calculate coefficient to gain concrete strength?

Solution- Coefficient to gain concrete strength= 21/(33*18*0.01)

Coefficient to gain concrete strength= 3.535

In below table coefficient to gain concrete strength data calculated by nominal mix ratio and its concrete grade which is prior decided.

How to calculate cement percentage by mix ratio?

Cement percentage by mix ratio= cement content in a unit*100/sum of all concrete content in a unit

Suppose concrete mix ratio is 1:2:4 then,

cement percentage= 1*100/(1+2+4)

Cement percentage= 100/7

Cement percentage= 14.286%

Coefficient to gain concrete strength by cement percentage, If sand and aggregate ratio would be 1:2.

| concrete grade or 28days concrete compressive strength in N/Sqmm | nominal mix ratio | cement percentage for cement grade 33N/Sqmm | Coefficient to gain concrete strength |

|---|---|---|---|

| M5 | 1:5:10 | 6.25% | 2.4242 |

| M7.5 | 1:4:8 | 7.692% | 2.954 |

| M10 | 1:3:6 | 10% | 3.0303 |

| M15 | 1:2:4 | 14.286% | 3.182 |

| M20 | 1:1.5:3 | 18.182% | 3.333 |

| M25 | 1:1:2 | 25% | 3.030 |

| M30 | 1:0.7:1.4 | 32.26% | 2.82 |

Coefficient to gain concrete strength by cement percentage with strength gain admixture, If sand and aggregate ratio would be 1:2.

Note- Coefficient to gain concrete strength is based on calculation not by lab test, only for your understanding. If you use admixture then we can calculate this coefficient after cube test. Here in the calculation we have increased 30% strength (Concrete grade) after 1% admixture use.

| concrete grade or 28days concrete compressive strength in N/Sqmm | nominal mix ratio | cement percentage for cement grade 33N/Sqmm with 1% admixture | Coefficient to gain concrete strength |

|---|---|---|---|

| M6.5 | 1:5:10 | 6.25% | 3.151 |

| M9.75 | 1:4:8 | 7.692% | 3.840 |

| M13 | 1:3:6 | 10% | 3.939 |

| M19.5 | 1:2:4 | 14.286% | 4.137 |

| M26 | 1:1.5:3 | 18.182% | 4.329 |

| M32.5 | 1:1:2 | 25% | 3.939 |

Table shows that coefficient to gain concrete strength is very less if cement percentage less than 10%, if cement percentage 15% to 20% then coefficient maximum, and if cement percentage 10%-15% & 20%-32% then coefficient moderate. So used cement percentage between 15% to 20% for maximum concrete strength gain.

Note-use ‘coefficient to gain concrete strength’ after lab test with various cement percentage.

Example: Calculate the trial mix ratio for M30 grade concrete with OPC 43 grade of cement.

Solution:

Soved has created a formula for trial mix ratio calculation by grade of concrete, grade of cement, and related coefficient between cement grade and concrete strength after cube test with cement percentage. In a prior calculation we will take Coefficient to gain concrete strength as value 3.0303 and calculate cement quantity and cement percentage for trial mix. If cement percentage is higher than 20% then try to use admixture to increase concrete strength and keep cement percentage between 15% to 20% for maximum cement strength utilization.

Cement quantity in Cum= dry mix volume coefficient for 1Cum*concrete grade/(coefficient to gain concrete strength *cement grade)

Dry mix volume coefficient= 1.54

Concrete grade= 30N/Sqmm

Cement grade= 43N/Sqmm

Coefficient to gain concrete strength= 3.0303 (For prior calculation)

Cement quantity in cum= 1.54*30/(3.0303*43)

Cement quantity in cum= 0.3545

Cement quantity in percentage= cement quantity in a unit*100/dry mix volume in a unit

Cement quantity in percentage= 0.3545*100/1.54

Cement quantity in percentage= 23.02%

We know that if cement percentage between 15% to 20%, then concrete mix economical and get higher concrete strength.

But we get cement percentage 23.02% which is higher. So we will increase cement grade or use admixture to increase concrete strength. Here we will use admixture (Plasticizer or super plasticizer) to gain concrete strength because of its also improve workability, durability, and reduce water cement ratio etc.

According to lab cube test after using strength improvement admixture, Found concrete strength increased 30% to 60%. Here we are not going to any lab test its only for your trial mix ratio calculation method so we are using admixture and after use of admixture our concrete strength increased about 30%.

So our coefficient to gain concrete strength also increased 30%.

So Coefficient to gain concrete strength with admixture= 3.0303*1.3

Coefficient to gain concrete strength with admixture= 3.94

What is plasticizer and super plasticizer?

A plasticizer is a substance or material added to concrete to make it softer, improve workability and strength, and reduce water requirements. Plasticizers are available in two forms: mineral admixtures, like fly ash, and chemical admixtures, like Superplasticizers.

Now if used admixture,

cement quantity in cum= 1.54*30/(3.94*43)

Cement quantity in cum= 0.2727

Cement quantity in percentage= 0.2727*100/1.54

Cement quantity in percentage= 17.71%

Its cement percentage with admixture between 15% to 20% so this is good. Now we will calculate other trial ratio.

Sand plus aggregate quantity= 1.54 – cement quantity

Sand plus aggregate quantity= 1.54 – 0.2727

Sand plus aggregate quantity=1.2673

Generally sand quantity uses half of the aggregate quantity in concrete mix or after by voids calculation test we decide sand and aggregate ratio, Now here we are taking Sand and Aggregate ratio is 1:2

Sand quantity= Sand plus Aggregate quantity*Sand ratio/sum of sand and aggregate ratio

Sand quantity= 1.2673*1/(1+2)

Sand quantity= 0.4224

Aggregate quantity= 1.2673*2/(1+2)

Aggregate quantity= 0.8448

So, Trial mix ratio= cement qty/cement qty : sand qty/cement qty : aggregate qty/cement qty

Trial mix ratio= 0.2727/0.2727 : 0.4224/0.2727 : 0.8448/0.2727

Trial mix ratio= 1 : 1.55 : 3.1

If 10mm aggregate and 20mm aggregate to be used in the ratio of 1:2 instead of graded aggregate then trial mix ratio,

Trial mix ratio=1 : 1.55: 3.1*1/3 : 3.1*2/3

Trial mix ratio=1 : 1.55 : 1.04 : 2.06

This trial mix ratio is approximate, you can mingle cube test with this Soved calculator and easily you can design your mix ratio.

Now for weight qty, we have taken bulk density for Cement 1440Kg/cum, for Sand 1600Kg/cum, and for Aggregate 1450Kg/cum. If bulk density is different then take by own bulk density test without rodded and input value in calculator.

For 10mm, 20mm, and 40mm Aggregate use ratio 1:2:4, or design by void test for ratio calculation.

What is the importance of water cement ratio and how to calculate for concrete mix?

In the concrete mix, water cement ratio is more important. If water cement ratio, more than or less than a defined value then concrete strength to be reduced. Soved is sharing some snapshot from IS code 456. In which we can see maximum free water per bag or maximum free water cement ratio.

For hydration of cement with all chemical reaction approximate water required 23% by weight of cement, And for voids of cement or workability 10% to 15% extra water required. So total water requirements for hydration and gel forming is 33% to 38%.

So formula for water cement ratio,

Water requirement for concrete mix by cement weight= 23% for Cement hydration + 10% to 15% for Cement voids and workability + x% If absorb water by sand and aggregate – x% If moisture available in sand and aggregate

Water cement ratio= water weight/cement weight

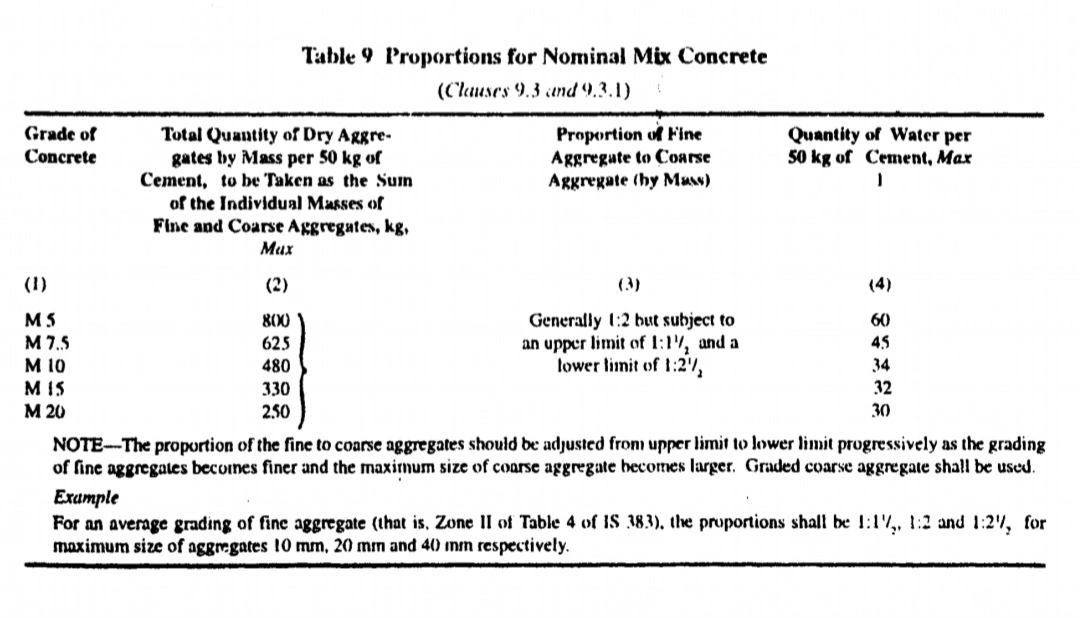

In above image, Maximum water requirement per 50kg cement bag given by grade wise of concrete for nominal mix concrete.

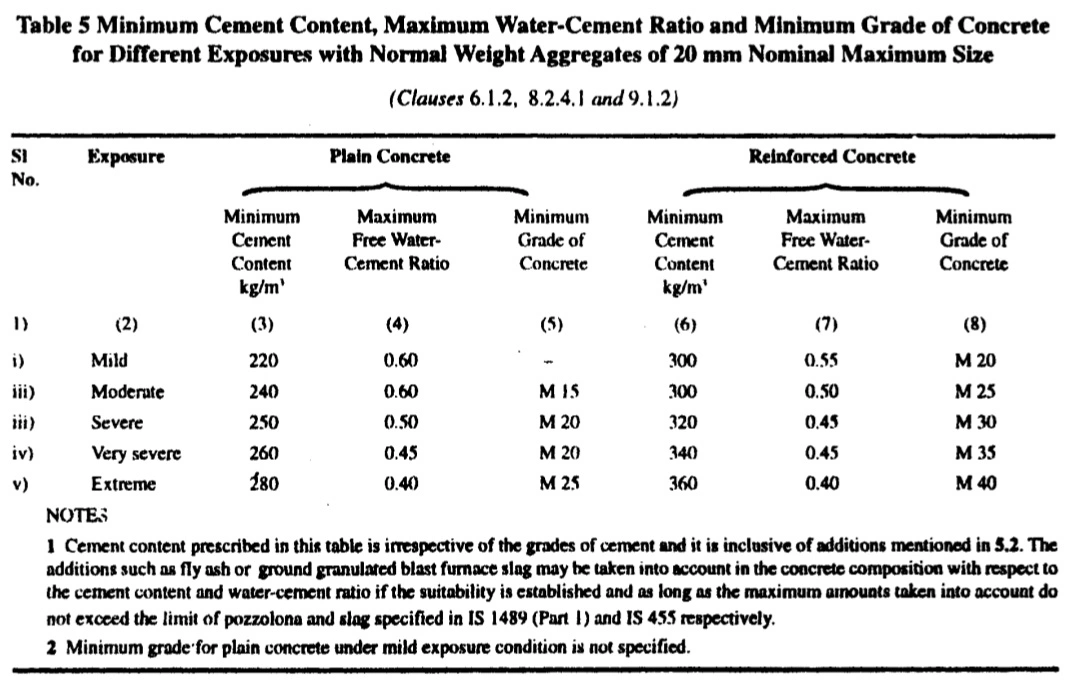

In above image, Maximum water cement ratio given by exposure condition, for plain concrete mix and reinforced concrete mix.

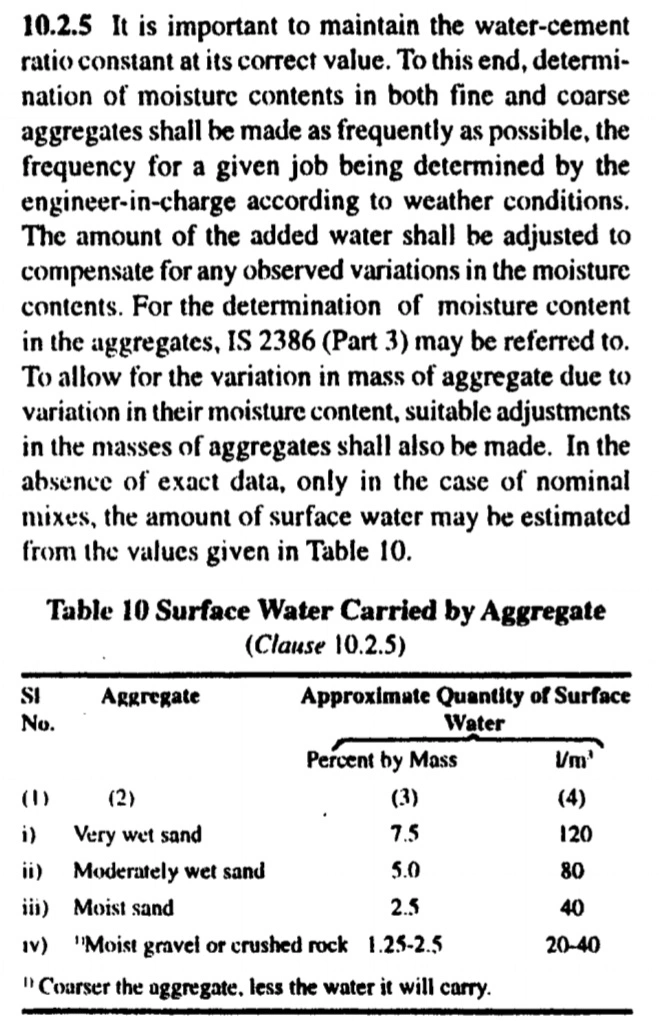

In a moisture condition of sand and aggregate, surface water carries by sand and aggregate, which is approximate given in above image.

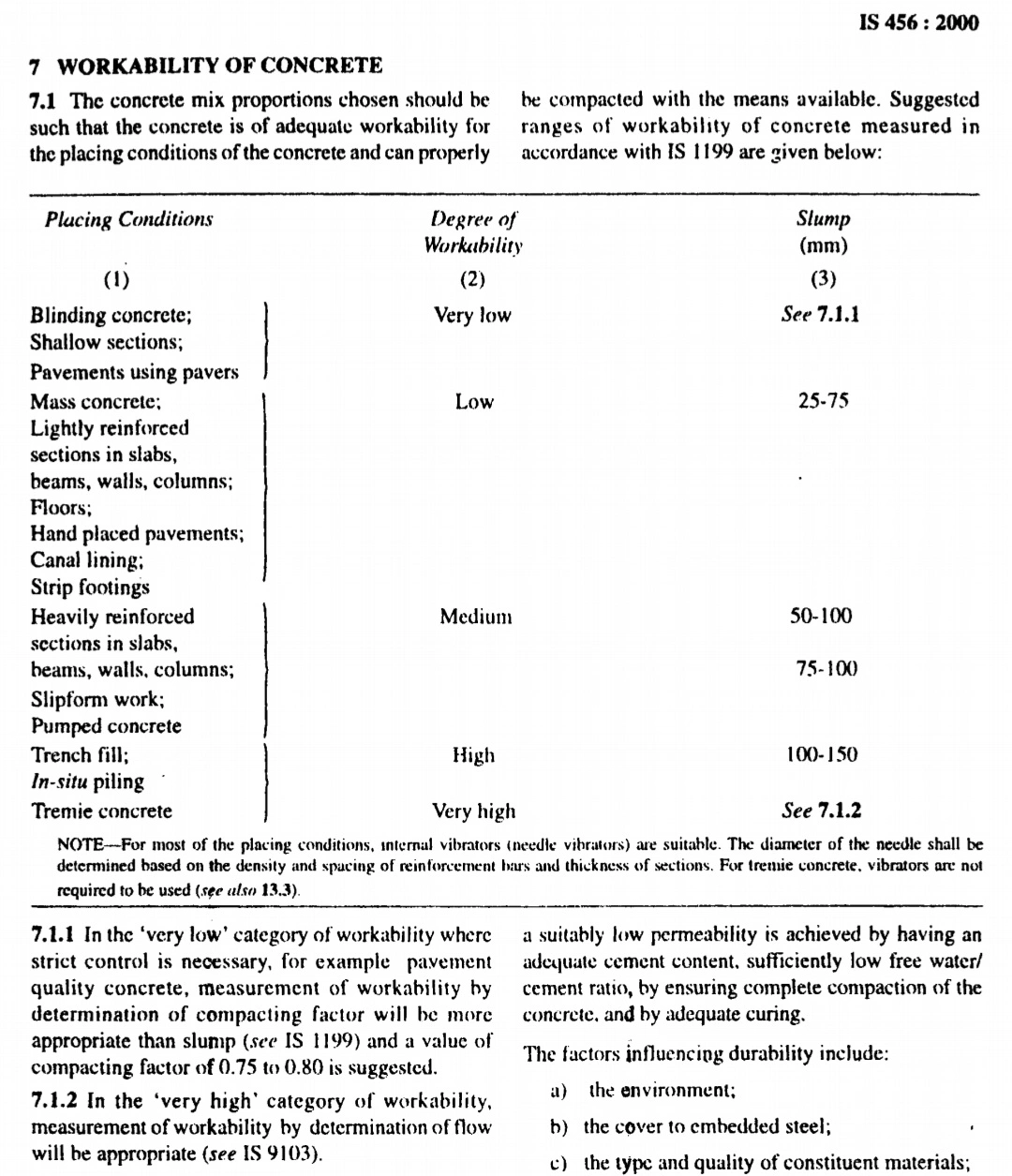

Above image shown workability of concrete mix. According to our requirement of slump, we can reduce or increase water requirements with the mind of 100% concrete compaction.

In market some admixtures available to reduce water requirements, use them if water cement ratio is more than 33% to 38%, because of less water cement ratio high the concrere strength, but not less than 33%.